Building Connections, Driving Success

We welcome you to Unity Group

It began over a decade ago — with a vision to shape not just metal, but lasting value. Since then, Unity Forgings has grown into a trusted name in precision forging, partnering with OEMs who demand strength, reliability, and excellence.

From the moving parts of forklifts to the heart of electric motors, from rugged construction machinery to the depths of mines and drilling sites, our components are forged to perform where it matters most.

Every product we create carries the weight of experience, the precision of craftsmanship, and a commitment to quality that never wavers. At Unity Forgings, we don’t just forge metal, we forge trust, resilience, and enduring partnerships.

Board of Directors & Management Team

Mahendra Parmar

Sanjay Kambli

Dr. Akshay Parmar

Parag Shah

Rajkumar Vijan

Our Strengths

In-house die, tool, and fixture designing / manufacturing capabilities.

Quality Assurance

Designing, Manufacturing & QC

Cost-Competitive Process Improvement

Commitment to Customer’s Requirements

On-Time Deliveries

Dedicated R & D Laboratory

Our Clients & Partners

Trusted by leading OEMs across India and internationally, Unity Group continues to build strong, long-term partnerships based on reliability, quality, and service excellence.

Our Capabilities

Unity Group provides end-to-end manufacturing services under one roof

Forging

● Friction Drop Hammers

● Automatic & manual bar cutting machines

● EOT crane

● In-house tool room for precision die making

Machining Facilities

● CNC turning centers

● VTL for large components

● VMC machines with auto-probing

● Pre-CNC operations: centering, facing, drilling

● Dot matrix marking machines for traceability

Gear & Shaft Manufacturing

Gear Hobbing:

● Vertical & horizontal machines

Gear Shaving:

● Shaving machines

● Enhances surface finish for improved gear meshing

● Reduces noise, vibration, and improves overall gear efficiency

Straight Bevel Gears:

● Delivers consistent and precise bevel gear profiles

● Ensures reliable power transmission with smooth rotational motion

Tooth Rounding & Chamfering:

● Cutter Sharpening - We maintain in-house hob and cutter sharpening for consistent accuracy.

Heat Treatment - Gears & Shafts

Forged Components

● Automated normalising furnace

● ISO-standard annealing furnace

● Eco-friendly LPG furnace systems

● Tumble-type shot blasting for finishing

Gears & Shafts

● Pit-type gas carburising furnaces

● Tempering furnace for gear hardening

● Spinner hanger-type shot blasting

● Hydraulic & mechanical straightening presses

Grinding Facilities

● Cylindrical grinding

● Surface grinding

● Bore grinding with precision ID grinders

● CNC grinding with auto-gauging

Inspection & Quality Control

● Meta-Vision Spectrometer for chemical analysis

● Carl Zeiss 3D CMM

● MAAG PH60 & SP60 gear testers

● Full range of micrometers, calipers, air/snap gauges

● Hardness testing: Brinell, Rockwell, Vickers

● Microscope for microstructure analysis

● MPI testing for crack detection

● Additional instruments: Ra tester, Mahr Trimos 2D, spline gauges, roll testers

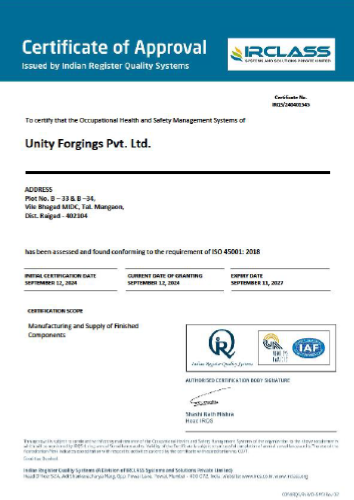

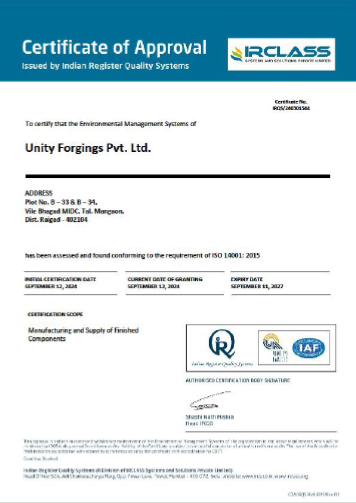

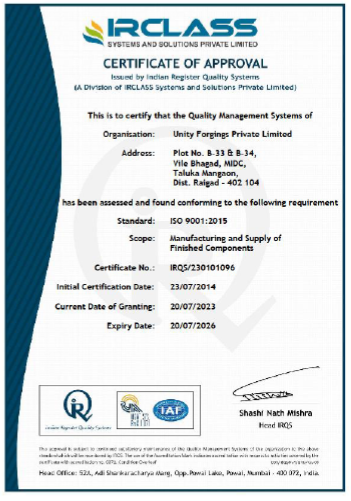

We Are ISO Certified!

ISO 14001:2015

ISO 9001:2015